MIL-DTL-3992F

4.3.1 Samples for qualification. Samples for qualification shall be representative of the products

proposed to be furnished to the Government. Samples shall be of one type and nominal size of hose

and shall be of the quantity and length specified in the applicable test method.

4.3.2 Qualification inspection routine. All samples shall be subjected to qualification testing in

accordance with table VIII the sequence is at the manufacturer's discretion.

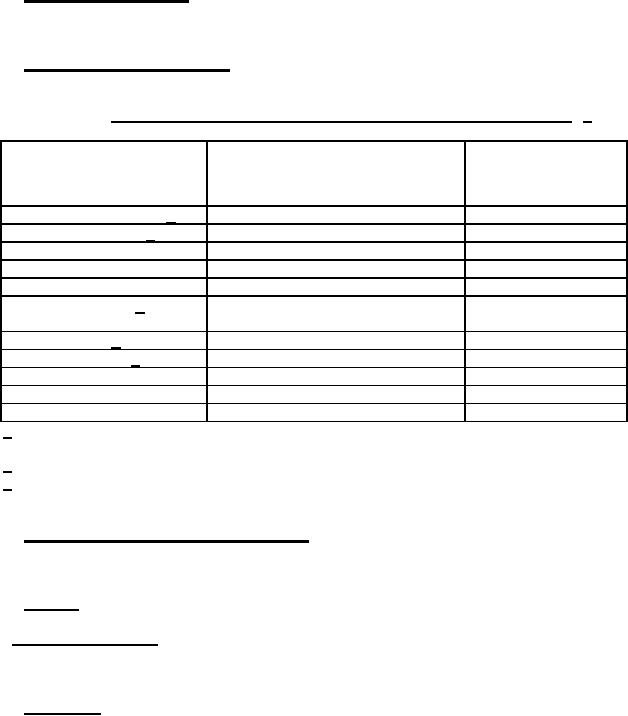

TABLE VIII. Qualification inspection for type I (air brake) hose and hose assembly. 1/

Inspection

Qualification Inspection

Requirement paragraph

paragraph

Examination of product 2/

Hydrostatic bursting 2/

Adhesion

Ozone resistance

Oil immersion

Fungus resistance 3/

hydrostatic bursting

Proof pressure 2/

Assembly tension 2/

Elongation and contraction

High-temperature resistance

Low-temperature resistance

1/ Unless otherwise specified all tests apply to qualifying a hose assembly with previously

unqualified bulk hose.

2/ Applies to qualifying a hose assembly with already qualified bulk hose.

3/ At the discretion of the qualifying activity the manufacturer may verify conformance to 3.7.1.5

with a certificate of compliance stating testing has been completed in accordance with 4.8.2.5.

4.3.3 Acceptance of qualification inspection data. Required qualification tests at the hose assembly

level that were already performed at the bulk hose level may be eliminated if documented approval has

been obtained from the qualifying activity.

4.3.4 Failures. One or more failures shall be cause for refusal to grant qualification.

4.4 First article inspection. First article inspection shall be performed at a laboratory acceptable to the

procuring activity on sample units produced with equipment and procedures used in production. First

article inspection shall be performed on type II hoses and hose assemblies.

4.4.1 Lot records. Manufacturers shall keep lot records for 3 years minimum. Manufacturers shall

monitor for compliance to the prescribed procedures, and observe that satisfactory manufacturing

conditions and records on lots are maintained for these hose assemblies. The records, including as a

minimum, an attributes summary of all quality conformance inspections conducted on each lot, shall be

available to review by customers at all times.

13

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business