MIL-DTL-3992F

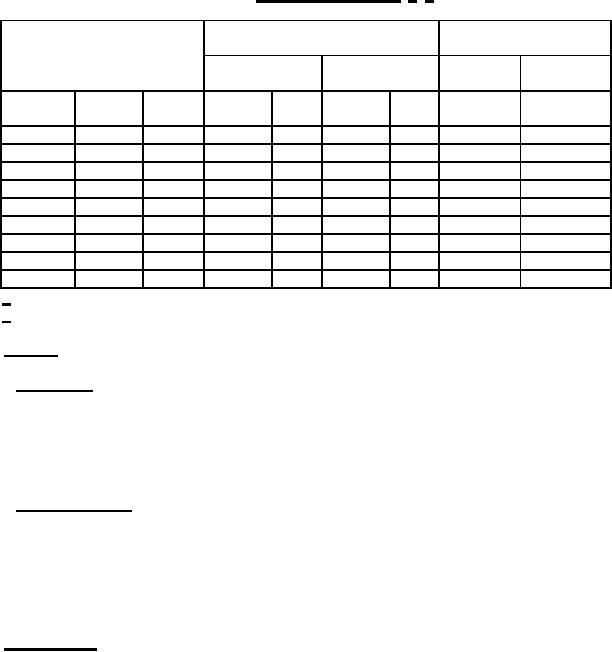

TABLE VII. Bend test dimensions. 1/ 2/

Maximum collapse of

Length of specimen

OD (% of OD)

Inside diameter of hose

Heavy

Light

Heavy

Light

wall

wall

wall

wall

Inches

Inches metric

inches

mm

inches

mm

---

40%

fraction decimal (mm)

7/32

.219

5.56

---

---

7

180

20%

---

1/4

.250

6.35

8

205

---

---

---

30%

11/32

.344

8.73

---

---

11

280

20%

---

3/8

.375

9.53

12

305

---

---

20%

30%

15/32

.469

11.91

---

---

14

355

20%

---

1/2

.500

12.70

16

405

---

---

20%

---

5/8

.625

15.88

22

560

---

---

20%

---

3/4

.750

19.03

28

710

---

---

20%

---

1

1.00

25.40

36

915

---

---

20%

---

1/ Dimensions are in inches.

2/ Metric equivalents are given for information only.

3.8 Marking. Marking shall be in accordance with MIL-STD-130.

3.8.1 Hose cover. The hose cover material shall have the following information legibly marked on the

lay line of the hose at intervals of not more than 15 inches (381 mm):

a. PIN (see 1.2).

b. Date of manufacture (quarter (1 thru 4) and year (05) two numbers.

c. Manufacturer's CAGE

3.8.2 Hose assemblies. Each hose assembly shall be identified by means of a band around the hose.

The band may move freely along the length of the assembly. The band shall be permanently embossed,

etched or stamped with the following information:

a. PIN (see 1.2)

b. Date of assembly (quarter (1 thru 4) and year (05) two numbers)

c. Manufacturer's CAGE

3.9 Workmanship. Workmanship to produce hose or hose assemblies shall be in accordance with the

best current manufacturing practice as to be uniform in quality and shall be free from burrs, crazing,

cracks, voids, pimples, chips, blisters, pinholes, sharp cutting edges, and other defects that will adversely

affect life, serviceability, or appearance.

11

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business