MIL-DTL-3992F

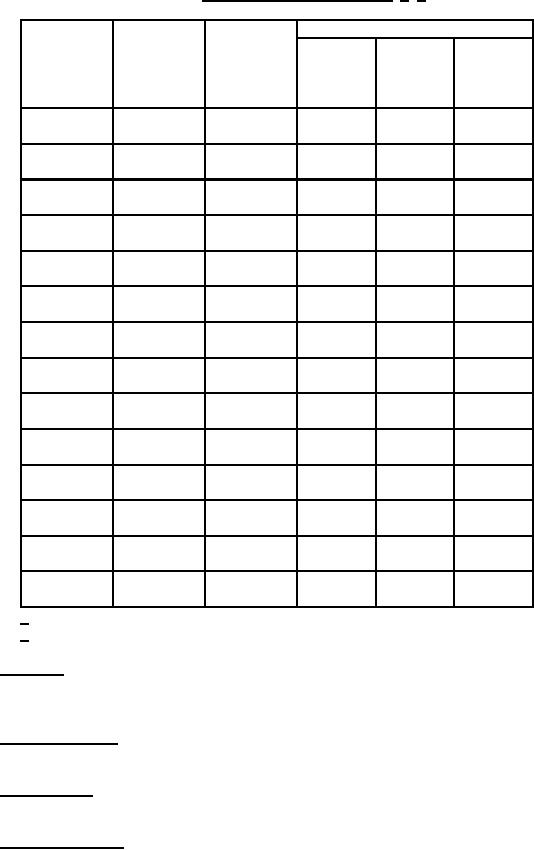

TABLE VI. Burst pressure requirements. 1/ 2/

Burst pressure

Nominal

Nominal

Nominal

Type I

Type I

Type II

hose size

hose size

hose size

Classes

Classes

Styles

inches

inches

metric

1 and 2

3 and 4

A and B

fraction

decimal

(mm)

psi (bar)

psi (bar)

psi (bar)

900

10,000

---

3/16

.188

4.76

(62.0)

(689.5)

350

7/32

.219

5.56

---

---

(24.13)

900

10,000

1,200

1/4

.250

6.35

(62.0)

(689.5)

(82.74)

900

9,000

---

5/16

.3125

7.94

(62.0)

(620.5)

350

11/32

.344

8.73

---

---

(24.13)

900

8,000

1,200

3/8

.375

9.53

(62.0)

(551.6)

(82.74)

900

8,000

1,200

13/32

.406

10.32

(62.0)

(551.6)

(82.74)

900

7/16

.438

11.11

---

---

(62.0)

350

15/32

.469

11.91

---

---

(24.13)

900

7,000

1,000

1/2

.500

12.70

(62.0)

(482.6)

(68.95)

900

6,000

1,000

5/8

.625

15.88

(62.0)

(413.7)

(68.95)

900

5/8 Special

.625

15.88

---

---

(62.0)

800

3/4

.750

19.05

---

---

(55.16)

800

1

1.00

25.40

---

---

(55.16)

1/ Dimensions are in inches.

2/ Metric equivalents are given for information only.

3.7.1.2 Adhesion. When tested as specified in 4.8.2.2 the hose specimens shall show no separation

of the plies, the tube from the plies or the cover from the plies upon application of a load of not less than

10 pounds per 1 inch (4.53 kg per 25.4 mm) of hose width.

3.7.1.3 Ozone resistance. When tested as specified in 4.8.2.3 the hose outer cover specimens cut

from untested hose shall exhibit no cracking after exposure to ozone.

3.7.1.4 Oil immersion. When tested as specified in 4.8.2.4 hose specimens shall not demonstrate a

volume increase greater than 100%.

3.7.1.5 Fungus resistance. When tested as specified in 4.8.2.5 hose and hose assemblies shall be

fungus resistant. After being exposed to fungus, specimens shall meet the length change requirements

of 3.7.2.3.

9

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business