MIL-DTL-3992F

3.3.1 Recycled, recovered, or environmentally preferable materials. Recycled, recovered, or

environmentally preferable materials should be used to the maximum extent possible provided that the

material meets or exceeds the operational and maintenance requirements, and promotes economically

advantageous life cycle cost.

3.4 Design and construction.

3.4.1 Bulk hose.

3.4.1.1 Inner tube. The inner tube shall consist of a synthetic rubber compound capable of meeting

the requirements of this specification including exposure to hydrocarbon test fluid (see 3.7.1.4). The inner

tube shall have a smooth bore; it shall be free of pitting, cracks and other recognizable defects. The bore

shall be free of dirt and other foreign material and shall not contain residual mandrel lubricant to the

extent that the requirements of this specification cannot be met.

3.4.1.2 Reinforcement. The hose shall have a reinforcement of cotton or synthetic fiber yarn or fabric,

steel wire, or a combination thereof.

3.4.1.3 Outer cover. The outer cover shall consist of a synthetic rubber compound that meets the

requirements of this specification. The outer cover shall be of uniform thickness and be free of cuts,

breaks, blisters and other recognizable defects.

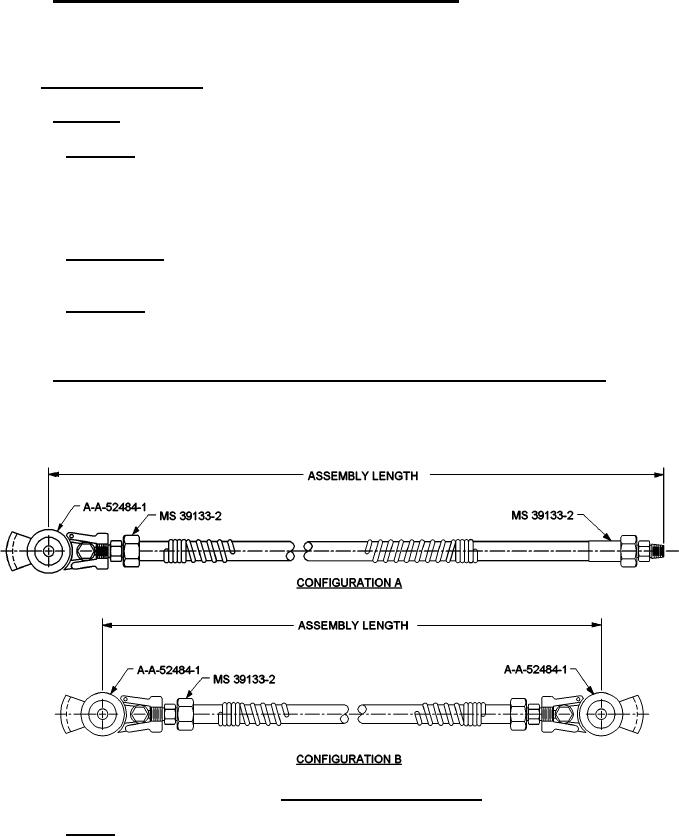

3.4.2 Hose assembly (see MS39325 for 3/8 inch (.375 inch) (9.53 mm) hose assemblies). Hose

assemblies shall be constructed of hose (see 3.4.1) with fittings assembled on each end (see figure 1).

The default configuration for the assemblies shall be one male fitting and one female fitting. An alternate

configuration shall be two female fittings.

FIGURE 1. Hose assembly configurations.

3.4.2.1 Fittings. Dimensions and materials shall conform to the requirements of A-A-52484 or

MS39133. Fittings shall be corrosion resistant or shall be protected to resist corrosion during the length

of the service.

6

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business