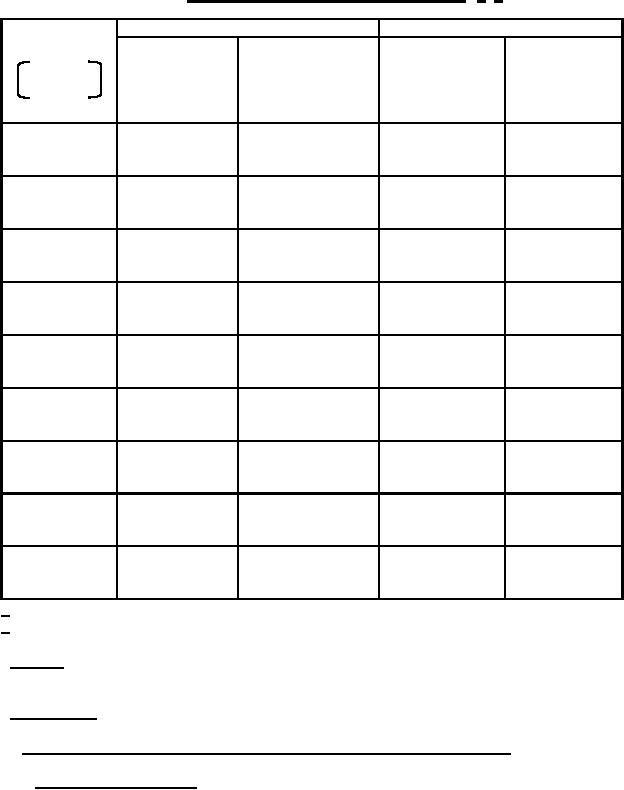

MIL-DTL-3992F

TABLE V. ID and OD diameter tolerances for type II. 1/ 2/

Inside diameter

Outside diameter

Nominal size

I.D.

inches

Style A

Style B

Style A

Style B

fraction

±. 031

±. 031

(mm)

(mm)

decimal

(0.79 mm)

(0.79 mm)

metric (mm)

7/32

+0.028, -0.032

.437

.219

---

---

(+0.71, -0.81)

(11.10)

(5.56)

1/4

+0.008, -0.020

.562

---

---

.250

(0.20, -0.51)

(14.27)

(6.35)

11/32

.687

+0.028, -0.032

---

.344

---

(17.45)

(+0.71, -0.81)

(8.73)

3/8

.812

+0.008, -0.020

---

---

.375

(20.62)

(0.20, -0.51)

(9.53)

15/32

+0.028, -0.032

.812

.469

---

---

(+0.71, -0.81)

(20.62)

(11.91)

1/2

.937

+0.008, -0.020

---

---

.500

(23.80)

(0.20, -0.51)

(12.70)

5/8

+0.008, -0.020

1.062

---

---

.625

(0.20, -0.51)

(26.97)

(15.88)

3/4

1.812

+0.008, -0.020

---

---

.750

(46.02)

(0.20, -0.51)

(19.05)

1

+0.010, -0.022

1.469

---

---

1.00

(0.25, - 0.56)

(37.31)

(25.40)

1/ Dimensions are in inches.

2/ Metric equivalents are given for information only.

3.6 Lengths. Hose and hose assemblies shall be furnished in lengths specified in the procurement

documentation (see 6.2).

3.7 Performance.

3.7.1 Requirements applicable to both type I and II hoses and hose assemblies.

3.7.1.1 Hydrostatic bursting test. The hose shall not burst or show signs of failure and the hose

assemblies shall not leak at any hydrostatic pressure up to and including that shown in table VI see

8

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business