MIL-DTL-26633E

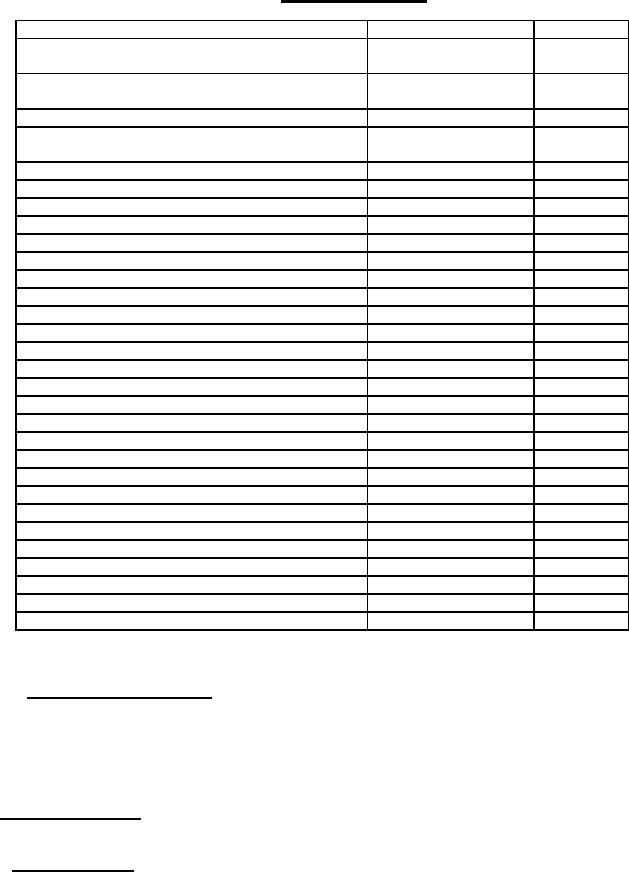

TABLE I. Workmanship defects.

Defect

Inspection

Reference

Dimensions affecting interchangeability

Standard inspection

3.3.2.3 and

not within tolerance

equipment (SIE)

Hose inside diameter at fitting junction out

SIE

of tolerance

(hose assembly only)

Under gage cover area

Visual

Depressed area, groove longitudinal corrugations

Visual

N/A

(exceeding specified tolerance)

Ridge on tube - Severe

SIE

N/A

Bunching of tube - Severe

SIE

N/A

Loose tube

SIE

N/A

Off center -under gage cover

SIE

N/A

Hole in tube

SIE

N/A

Restriction in the tube

SIE

N/A

Nad lap or delamination of tube

SIE

N/A

Reinforcement through tube

SIE

N/A

Broken or spliced reinforcing wires

Visual

Reinforcement through cover

Visual

N/A

Poorly patched cover

Visual

N/A

Blistered or loose, patch on cover

Visual

N/A

Poor coverlap, opening or lack of adhesion

Visual

N/A

Cover missing

Visual

N/A

Loose cover (wrinkles when bent)

Visual

N/A

Exposed reinforcement braid

Visual

N/A

Split, slit or break in cover

Visual

N/A

Blister under cover

Visual

N/A

Misbranding

Visual

Bulge behind the coupling

Visual

N/A

Cocked couplings

Visual

N/A

Cracked couplings

Visual

N/A

Freedom of swivels

Visual

N/A

Rusted couplings

Visual

N/A

Protective caps or plugs

Visual

N/A

Internal contaminants

SIE

N/A

4. VERIFICATION

4.1 Classification of inspections. The inspection requirements specified herein are classified as

follows:

a. Qualification inspection (see 4.4).

b. Conformance inspection (see 4.5).

4.2 Inspection conditions. Unless otherwise specified, all inspections shall be performed in accordance

4.2.1 Testing conditions. Unless otherwise specified, room temperature shall be defined as 60°F to 90°F

(15.56°C to 32.22°C).

8

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business