MIL-DTL-26633E

4.6.3 Periodic inspection samples.

4.6.3.1 Number of periodic hose assembly samples. For each size manufactured under essentially

the same conditions, periodic control testing shall be performed on either four (4) samples from every

10,000 hose assemblies produced (large lot option) or 1 sample from every 2,500 hose assemblies. If

there has been some production but the number hose assemblies produced has not reached 2,500 for a

specific size within three years, the manufacturer shall perform periodic control tests on 1 hose

assemblies of that size unless documented approval has been obtained from the qualifying activity.

Required periodic control tests at the hose assembly or fitting level that were already performed at the

bulk hose level may be eliminated if documented approval has been obtained from the qualifying activity.

Periodic samples may be subjected to more than one periodic test at the discretion of the manufacturer.

However, the manufacturer assumes the risk that the effect of one test will not have a detrimental impact

on the following test.

4.6.3.2 Periodic hose assembly samples. Hose assemblies shall be fabricated using the same

manufacturing techniques, processes, and procedures used to supply hose assemblies to this

specification. The hose assembly samples shall be 18 ±6 inches (45.72 ± 15.24 cm) long. The hose

assemblies shall be tested in accordance with the individual inspections in table III, except cleanliness,

and then subjected to the periodic testing in table V.

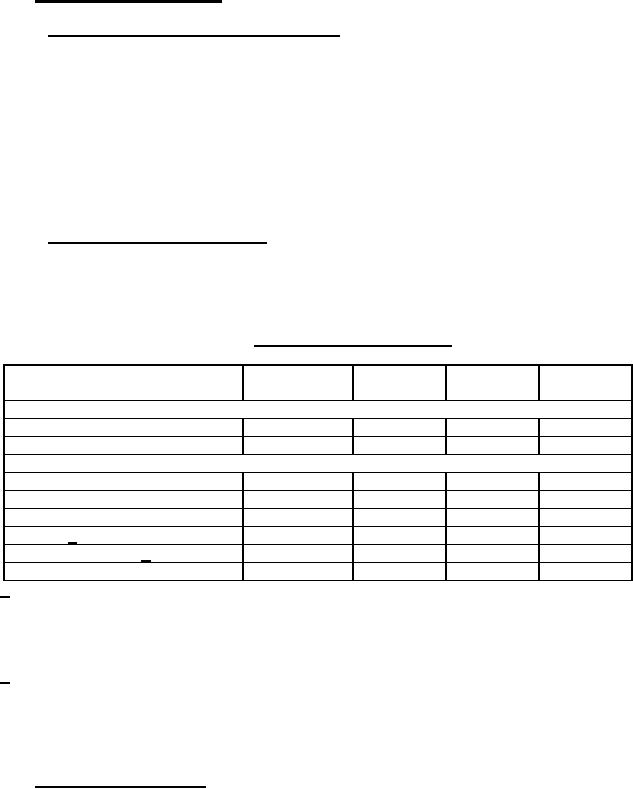

TABLE V. Sampling and periodic testing.

Requirement

Inspection

Sampling

Periodic

Test

paragraph

paragraph

Test on PTFE inner tube

Density and relative density

X

Tensile test and elongation

X

Hose and hose assembly tests

Leakage

X

Burst

X

Elongation and contraction

X

Impulse 1/

X

Stress degradation 2/

X

Tensile strength

X

1/ Impulse (periodic test) - The production count of MIL-DTL-26633 assemblies, and the production

count for SAE-AS1339 assemblies, may be combined due to similarity (instead of maintaining

independent counts), for the purpose of determining when the periodic test is due, with the

approval of the qualifying activity. The actual test may be performed on either type of hose

assembly.

2/ Stress degradation (periodic test) - The production count of MIL-DTL-26633 assemblies, and the

production count for SAE-AS1339 assemblies, may be combined due to similarity (instead of

maintaining independent counts), for the purpose of determining when the periodic test is due,

with the approval of the qualifying activity. The actual test may be performed on either type of

hose assembly.

4.6.4 Periodic nonconformance. If a sample fails to pass any periodic inspection, see table V, the

manufacturer shall immediately notify the qualifying activity and cognizant inspection activity of such

failure. The manufacturer shall take corrective action on the materials or processes or both as

warranted, on all units of product which can be corrected and which were manufactured under

essentially the same conditions, with essentially the same materials and processes, and which are

considered subject to the same failure. Acceptance of the product shall be discontinued until corrective

action acceptable to the qualifying activity has been taken.

12

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business