MIL-DTL-26633E

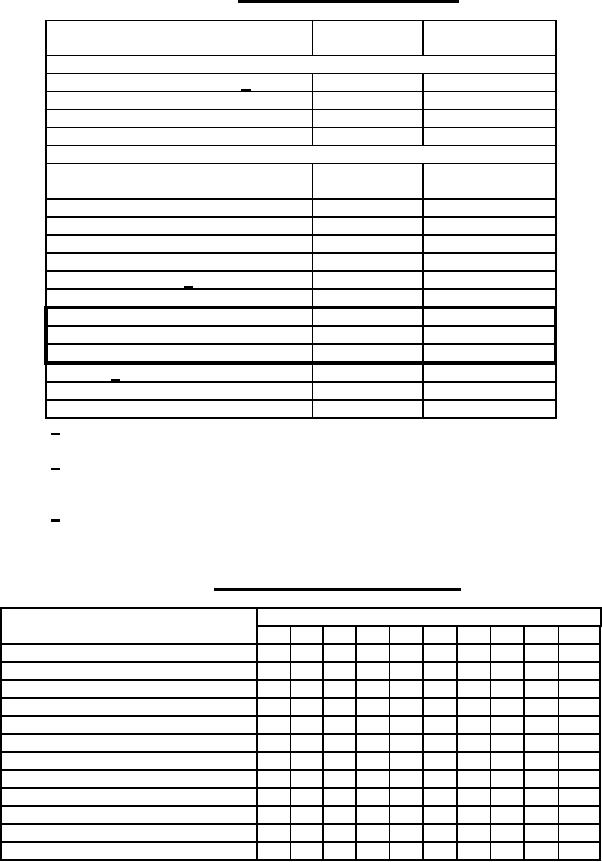

TABLE II. Qualification inspection and tests.

Requirement

Inspection

Test

paragraph

paragraph

PTFE inner tubes

Density and relative density 1/

Tensile test and elongation

Tube rolling

Tube proof pressure

Hose assembly

Examination of products

Configuration

Cleanliness

Proof pressure

Leakage

Stress degradation 2/

Elongation and contraction

Burst pressure

Room temperature burst pressure

High temperature burst pressure

Impulse 3/

Tensile strength

Overtightening torque

1/ A representative cross sections of the PTFE tube (see SAE-ARP1153

and ASTM D792).

2/ Stress degradation (qualification test) - This test may be qualified due to similarity to

hose assemblies qualified and tested in accordance with SAE-AS1339, with the

approval of the qualifying activity.

3/ Impulse (qualification test) - This test may be qualified due to similarity

to hose assemblies qualified and tested in accordance with

SAE-AS1339, with the approval of the qualifying activity.

TABLE III. Qualification inspection requirements.

Sample number

Test

1

2

3

4

5

6

7

8

9

10

Examination of product

X

X

X

X

X

X

X

X

X

X

Configuration

X

X

X

X

X

X

X

X

X

X

Cleanliness

X

X

Proof pressure test

X

X

X

X

X

X

X

X

X

X

Leakage test

X

X

X

X

X

X

X

X

X

X

Elongation and contraction

X

X

Tensile strength

X

X

X

X

Burst pressure (room temperature)

X

X

Burst pressure (high temperature)

X

X

Overtightening torque

X

X

Stress degradation

X

X

Impulse

X

X

10

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business