MIL-DTL-83298C

3.3 Recycled, recovered, or environmentally preferable materials. Recycled, recovered, or

environmentally preferable materials should be used to the maximum extent possible provided that the

material meets or exceeds the operational and maintenance requirements, and promotes economically

advantageous life cycle costs.

3.4 Design and construction. The hose shall be so designed and constructed that, when assembled

with approved end fittings in accordance with MIL-DTL-83296; the resulting hose assemblies shall meet

the requirements of this specification and MIL-DTL-32330.

3.4.1 Tube. The tube shall be a seamless extrusion of virgin polytetrafluoroethylene resin. Base

resin shall conform to ASTM D4895, except for the specific gravity (SG) requirements. Additives may be

included in the compound from which the tube is extruded.

3.4.1.1 Reinforcement. The reinforcement shall be braided corrosion-resistant stainless steel wire,

uniform in quality and size, and of sufficient strength to insure that the hose shall meet the requirements

specified herein. There shall be no broken or spliced reinforcing wires nor shall any wires be omitted in

any length of hose. Corrosion resistant steel shall be passivated in accordance with SAE-AMS2700,

method 2 (see 6.7.1).

3.4.1.2 Interlayers. Interlayers, if used, shall be resistant to or suitably protected from all fluids with

which the hose may come in contact. They shall be capable of withstanding temperature and pressures

specified in table I. Interlayers shall not extrude through the outer braid.

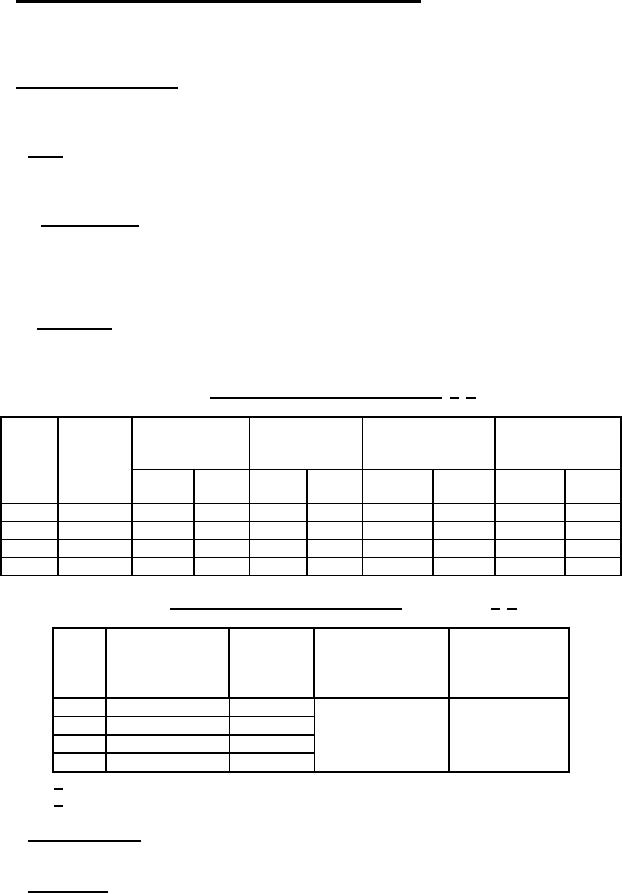

TABLE I. Performance requirements of hose. 1/ 2/

Min. burst

Min. burst

Maximum

Proof

Size

Hose

pressure at

pressure at

operating

pressure

dash

dia.

pressure

room temp

high temp

no.

fraction

psi

MPa

psi

MPa

psi

MPa

psi

MPa

-4

1/4

3,000

21

6,000

41

16,000

110

12,000

83

-6

3/8

3,000

21

6,000

41

14,000

97

10,500

72

-8

1/2

3,000

21

6,000

41

14,000

97

10,500

72

-10

5/8

3,000

21

6,000

41

12,000

83

9,000

62

TABLE I. Performance requirements of hose - Continued. 1/ 2/

Min. bend

Hydraulic

Size

Volume

Pneumatic

radius

temperature

dash

expansion

temperature

(inside of bend)

range

no.

(cc/in.)

range

inches (mm)

°F (°C)

-4

3.00 (76.2)

.065

-65°F to

-6

5.00 (127)

.085

-65°F to+160 °F

+400°F

-54°C to 71°C

-8

5.75 (146)

.135

-54°C to 204°C

-10

6.50 (165)

.220

1/ Dimensions are in inches.

2/ Metric equivalents are given for information only.

3.4.2 Hose end fittings. Hose end fittings required to test hose assemblies to the requirements of

this specification shall conform to MIL-DTL-83296 and the applicable detail specification sheet.

3.4.3 Dimensions. The hose dimensions shall be as specified in table II.

4

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business