MIL-DTL-83298C

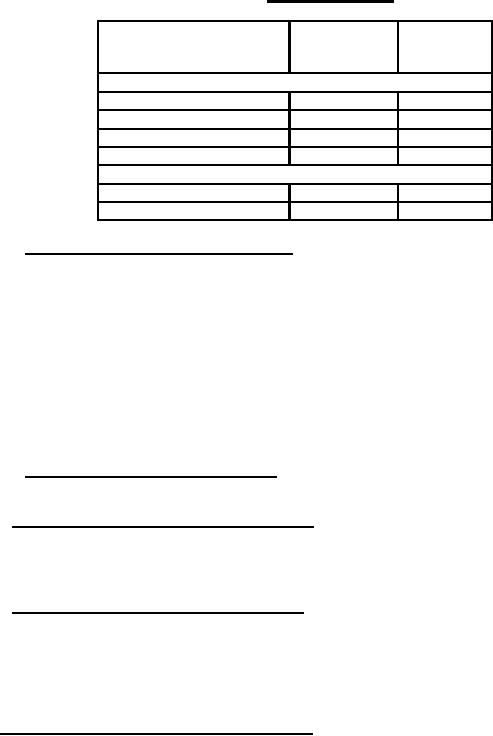

TABLE X. Periodic inspection.

Test

Requirement

Inspection or test

method

paragraph

paragraph

Tube

Specific gravity

Tensile strength

Elongation

Electrical conductivity test

Hose

Stress degradation

Impulse

4.5.4.3 Nonconformance of periodic inspections. If a sample fails a periodic control test, both the

qualifying and inspection activities shall be immediately notified of such failure. Acceptance and shipment

of the product shall be discontinued until corrective action, acceptable to the qualifying activity, has been

taken. The corrective measures shall be performed on the materials or processes, or both, as warranted,

and on all products considered subjected to the same failure. Once the corrective action has been

completed, either the specific periodic control test in which the original sample failed or all periodic control

tests may be required to be repeated on additional samples, at the option of the qualifying activity.

Furthermore, the sampling tests may be reinstituted in addition to the periodic control tests if deemed

applicable by the qualifying activity. However, final acceptance shall be withheld until testing has shown

that the corrective action was successful. In the event of a failure after re-inspection, information

concerning the failure and the corrective action taken shall be furnished to both the qualifying and

inspection activities.

4.5.4.4 Disposition of periodic test specimens. Samples that have been subjected to periodic control

tests are considered damaged and shall not be delivered as part of a contract or purchase order.

4.5.5 Discontinuation and resumption of production. If there has been no production of a specific

size for a period of three years or more, 16 samples shall be randomly selected from the first lot produced

when production of that size has been resumed. Eight of the samples shall be subjected to the sampling

tests and the remaining eight shall be subjected to the periodic inspections (see table X).

4.5.6 Acceptance of conformance inspection data. For identical requirements and test procedures,

using an identical fitting, conformance inspection data from MIL-DTL-83296 and MIL-DTL-32330 may be

accepted as conformance inspection data for MIL-DTL-83298, providing that documented approval has

been obtained from the qualifying activity. When conformance inspection data from MIL-DTL-83296 or

MIL-DTL-32330 is to be accepted as conformance inspection data for MIL-DTL-83298, one hose

assembly shall be considered to be the equivalent of two feet of bulk hose.

4.6 Additional QPL test and reporting requirements.

12

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business