MIL-DTL-13444H

4.6.3.1 Sampling for bulk hose. Sampling for bulk hose shall be performed on each continuous run

under essentially continuous conditions. Samples shall be selected at a rate of 1 sample for each full or

partial increment of 750 feet (228.60 m) of hose produced in the continuous run, up to a maximum of 2

samples (for continuous runs greater than 1,500 feet (457.20 m), 2 samples will be selected, but they

shall be representative of the entire production run). Sampling tests for length change and burst shall be

performed in the listed order on each sample as applicable. When a hose assembly is specified in the

test method, a hose assembly shall consist of the hose as specified herein, coupled with fittings as

specified in 3.5.5. Any subsequent changes regarding the sources of a fitting or bulk hose used in a

qualified assembly must be approved by the qualifying activity.

4.6.3.2 Hose assemblies. For hose assemblies, the inspection lot shall be 8 items tested for each

3000 assemblies produced (large lot option). At the option of the manufacturer, one item may be tested

for each 375 assemblies produced (small lot option). If there has been some production, but the number

hose assemblies produced has not reached 375 for a specific size within three years, the manufacture

shall perform sampling tests on one hose assembly of that size unless documented approval to not

perform the tests has been obtained from the qualifying activity.

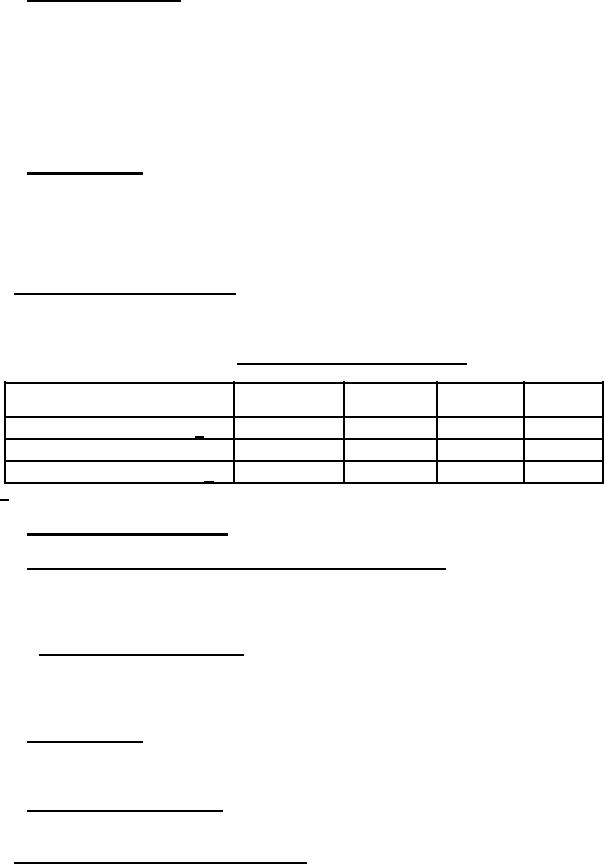

4.6.4 Sampling and periodic inspection. Sampling and periodic inspections shall consist of the

inspections specified in table VIII and shall be made on test samples from production lots which have

been subjected to and passed the individual inspections (see table VII).

TABLE VIII. Sampling and periodic inspections.

Requirement

Inspection

Sampling

Periodic

Inspections

paragraph

paragraph

Elongation and contraction 1/

X

---

Burst pressure

X

---

Vacuum collapse resistance 1/

---

X

1/ Elongation and contraction" and "vacuum collapse resistance" are for bulk hose only.

4.6.4.1 Periodic testing sampling plan.

4.6.4.2 Periodic quality conformance inspection (QCI) (Bulk hose only) . Periodic QCI will be 4

samples tested to each required periodic test for each produced 20,000 feet (6096 m) for bulk hose

specifications (large lot option). At the option of the manufacturer, 1 sample may be tested to each

required periodic test for each produced 5,000 feet (1524 m) as applicable (small lot option).

4.6.4.2.1 Reduced production bulk hose. If there has been some production, but the footage of bulk

hose produced has not reached 5,000 feet (1524 m) for a specific size within three years, the

manufacturer shall perform periodic control tests on one sample of that size, for each required periodic

test, unless documented approval to not perform the test has been obtained from the qualifying activity.

4.6.4.3 Periodic samples. Periodic samples may be subjected to more than one periodic test at the

discretion of the manufacturer. However, the manufacturer assumes all risk that the effect of one test

will not have a detrimental impact on the following test.

4.6.4.4 Disposition of test specimens. Test specimens that have been subjected to sampling and

periodic inspection in table VIII shall not be delivered on the contract or purchase order.

4.6.5 Acceptance of conformance inspection data. Required conformance tests at the hose assembly

level that were already performed at the bulk hose level may be eliminated if documented approval has

been obtained from the qualifying activity.

14

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business