MIL-DTL-13444H

4.7.8 Ozone resistance (see 3.6.5). Type I hose covers when subjected to ozone test in accordance

with ASTM D380 shall meet the requirements of 3.6.5. The following details shall apply:

a. The hose outer cover elongated 12.5(, shall be exposed for a period of 168 hours at a

temperature of + 100°F ± 2°F (+37.78°C ± 1.11°C) to an ozone concentration maintained at

50 ± 5 parts of ozone per hundred million parts of air.

b. During the duration of the test specimens shall be examined daily for cracking, visual

examinations shall be made without and with 7Xmagnification, except areas covered by tape

or twine. The first observable cracking shall be recorded.

d. After required exposure to ozone, the specimen shall be visually examined without and with

7X power magnification to determine conformance to 3.6.5.

4.7.9 Vacuum collapse resistance (see 3.6.6). Hose specimens when subjected to vacuum shall

meet the requirements of 3.6.6. The following details shall apply:

a. A piece of 36 inch (0.91 m) long hose shall be wrapped around a mandrel having a diameter as

specified in table X.

b. While bent around the mandrel, hose less than 1/2 inch (.500 inch) (12.70 mm) nominal size

shall be subjected to an internal vacuum equivalent to 20 inches of mercury (0.68 bar); hose

1/2 inch (.500 inch) (12.70 mm) and larger shall be subjected to an internal vacuum equivalent

to 10 inches of mercury (0.34 bar).

c. While vacuum is being applied, two readings spaced 90° apart shall be taken on the outside

diameter of the hose. The readings shall subsequently be averaged and the decrease

calculated as a percentage of the original outside diameter.

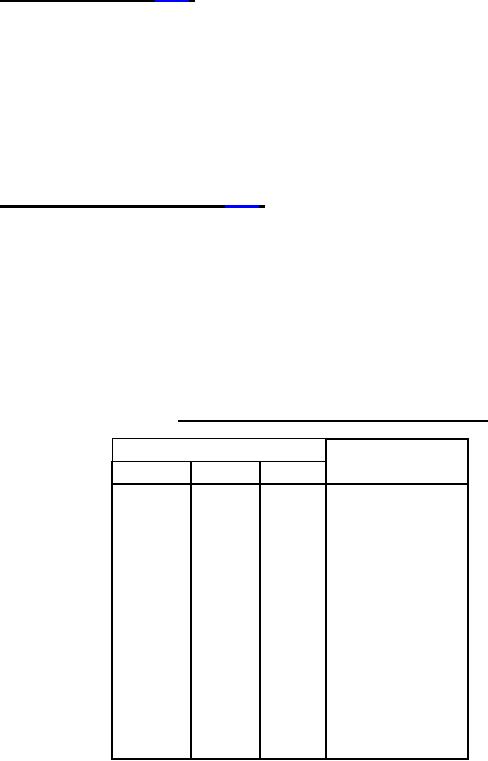

TABLE X Vacuum collapse resistance mandrel diameter.

Mandrel diameter

Hose size

inches (mm)

Fraction

Inches

Metric

1/8

.125

3.18

3.5 (88.90)

3/16

.188

4.78

4.0 (101.60)

1/4

.250

6.35

4.5 (114.30)

5/16

.313

7.95

5.5 (139.70)

3/8

.375

9.53

6.0 (152.40)

13/32

.406

10.31

7.0 (177.80)

1/2

.500

12.70

7.5 (190.50)

5/8

.625

15.88

9.5 (241.30)

3/4

.750

19.05

11.0 (279.40)

7/8

.875

22.23

12.0 (304.80)

1-1/8

1.125

28.58

15.0 (381.00)

1-3/8

1.375

34.93

16.0 (406.40)

1-13/16

1.813

46.05

20.0 (508.00)

19

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business