MIL-DTL-83797C

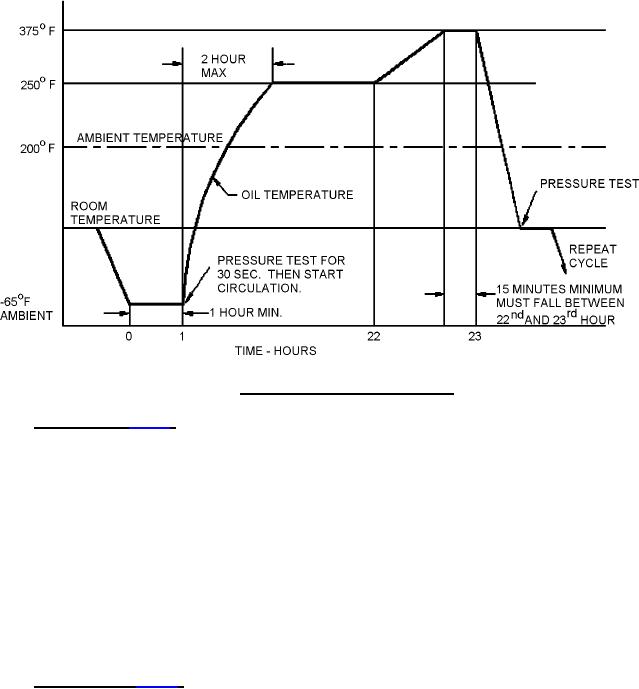

FIGURE 5. Oil circulation temperature cycle.

4.7.12 Leakage (see 3.5.12). Hoses, when subjected to the leakage test, shall meet the

requirements of 3.5.12. Leakage shall be tested in accordance with ASTM D380. The following details

shall apply:

a. Two un-aged samples shall be tested.

b. Test fluid shall be water or oil in accordance with MIL-PRF-7808, or hydraulic fluid in

accordance with MIL-PRF-5606, MIL-PRF-87257, or MIL-PRF-83282.

minutes.

d. After 5 minutes, the pressure shall be released and reduced to zero.

e. Then the pressure shall be raised again to 70% of the burst pressure and held for another 5

minutes.

f. The adjacent outer cover shall be carefully inspected during this period for any wicking or

leakage of the test fluid.

4.7.13 Corrosion (see 3.5.13). Hose assemblies, when subjected to corrosion, shall meet the

requirements of 3.5.13. The following details shall apply:

a. The hose assemblies shall be immersed, in a vertical position with the ends capped, into a 2.5

percent solution of sodium chloride for a minimum of 5 minutes.

b. The samples shall then be air dried for 25 minutes at a temperature of 140°F ± 5°F (60°C ±

2.8°C).

c. This immersion and drying cycle shall be repeated for a total of 168 hours.

d. Upon completion of this test the hose assemblies shall be subjected to the burst pressure test

(see 4.7.14).

22

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business