MIL-DTL-28693A

4.5.4.3 First article information. Upon completion of first article inspection, the Government activity

responsible for conducting the inspection program (see 6.2), shall report the results of the inspection,

with appropriate recommendation, to the contracting officer. Approval of the first article samples or the

waiving of first article inspection does not preclude the requirements for performing individual, or

sampling and periodic inspections.

4.5.4.4 Disposition of samples. First article samples shall be furnished to the Government as

directed by the contracting officer (see 6.2).

4.6 Conformance inspection. For manufacturers that have successfully passed first article

inspections and are continuously producing hose assemblies to this specification, on going inspections

shall consist of individual inspections, see table III.

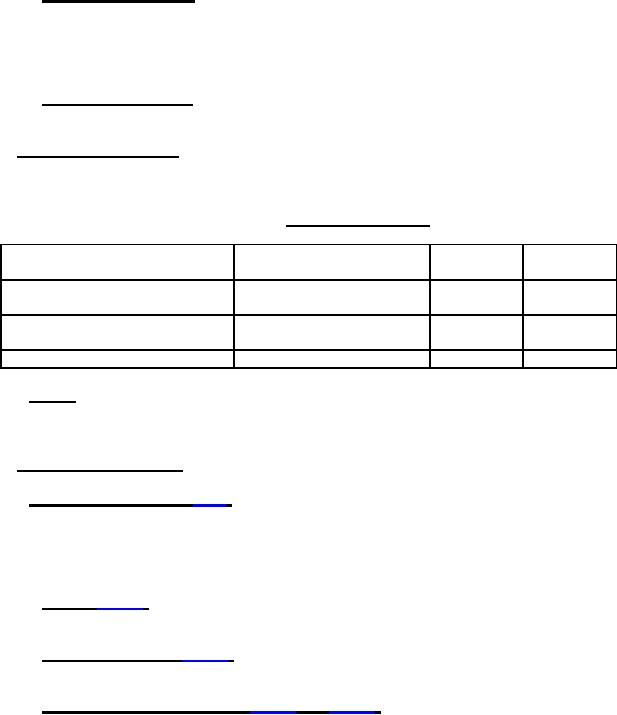

TABLE III. Individual inspections.

Requirement

Test

Samples

Test

paragraph

paragraph

Visual examination

All

Unit weight

All

(prior to assembly of couplings)

Proof pressure

All

4.6.1 Failure. Failure of an article sample to pass any of the inspections specified herein shall be

cause for the Government to refuse to accept further products until corrective action has been made and

successful completion of first article testing.

4.7 Performance inspections.

4.7.1 Visual examination (see 3.6.1). Each hose assembly and its related manufacturing records

shall be examined for compliance with the requirements specified herein with respect to dimensions,

identification of product, workmanship, cleanliness, interchangeability, and age limitations, see 3.4.3,

3.8, 3.9, 3.10, and 3.11. The classification of defects as specified in FED-STD-162 shall be used to

determine and evaluate defects through visual inspection.

4.7.1.1 Length (3.4.3.3). Hose selected shall be measured for length as specified in ASTM D380 to

determine conformance to 3.4.3.3.

4.7.1.2 Inside diameter (see 3.4.3.4). Hose selected shall have the ID measured as specified in

ASTM D380 to determine conformance to 3.4.3.4.

shall be measured on specimens removed from each end of the hose section obtained in accordance

with 4.5.3.2 to determine conformance to 3.4.3.1 and 3.4.3.2. The thickness shall be determined by the

procedure given in ASTM D380, except that only buffed specimens shall be measured. The respective

values found for the tube thickness shall not be averaged, but shall be regarded as independent

measurements, each of which shall meet the requirement. The respective values for the cover thickness

shall be treated in the same manner.

12

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business