MIL-DTL-26666G

4.6.3 Sampling and periodic inspection. Sampling and periodic inspections shall consist of the

inspections specified in table III and shall be made on test samples which have been subjected to and

passed the individual inspections (see table II).

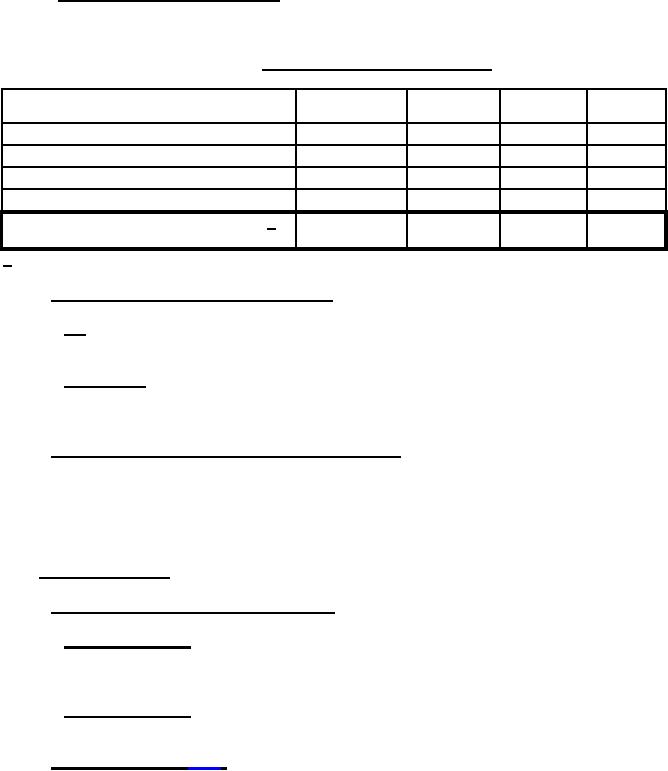

TABLE III. Sampling and periodic inspections.

Requirement

Inspection

Sampling

Periodic

Inspections

paragraph

paragraph

X

Leakage

Tensile strength

X

Overtighening torque

X

Burst pressure

X

Ambient temperature pressure cycling 1/

X

Leakage test

1/ Testing shall be performed in the order specified.

4.6.4 Sampling and periodic inspection samples.

4.6.4.1 Lot. A lot shall consist of hose assemblies manufactured under essentially the same

conditions and submitted for inspection at substantially the same time.

4.6.4.2 Lot samples. For each lot of five hundred hose assemblies or fraction thereof produced, four

hose assembly samples 18 inches ± 6 inches (5.49 m ± 182.88 cm) long shall be fabricated from random

samples of the bulk hose and end fittings using production processes and procedures.

4.6.5 Non conformance sampling and periodic inspections. In the event a failure should occur during

sampling or periodic inspection tests, specified in table III, then the production lot shall be screened for

that particular defect and defects removed. An inspection lot shall be selected from the production lot

and all sampling and periodic tests shall be performed. If one or more defects are found in the second

inspection lot, the production lot shall be rejected and shall not be supplied to this specification. Test data

of part performance shall be made available to the contracting agency upon request.

4.7 Inspection methods.

4.7.1 Visual examination and dimensional check.

4.7.1.1 Visual examination. The hose assembly shall be visually examined to ascertain whether both

ends are firmly sealed with a protective device and to determine conformance with respect to materials,

configuration and workmanship. The hose assembly shall meet the requirements specified in 3.5.1.1.

4.7.1.2 Dimensional check. The hose assembly shall be checked dimensionally to determine

conformance to the requirements specified in 3.5.1.2.

4.7.2 Proof pressure (see 3.5.2). The hose assembly when subjected to proof pressure shall meet

the requirements specified in 3.5.2. The following details shall apply:

a. The hose assembly shall be conditioned at not less than 160°F (71.11°C) for a minimum of

one hour.

b. Immediately after the conditioning period, the hose assembly shall be subjected to 8,000 psig

(551.58 bar) hydrostatic pressure for not less than 30 seconds or exceeding 5 minutes.

10

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business