MIL-DTL-13444H

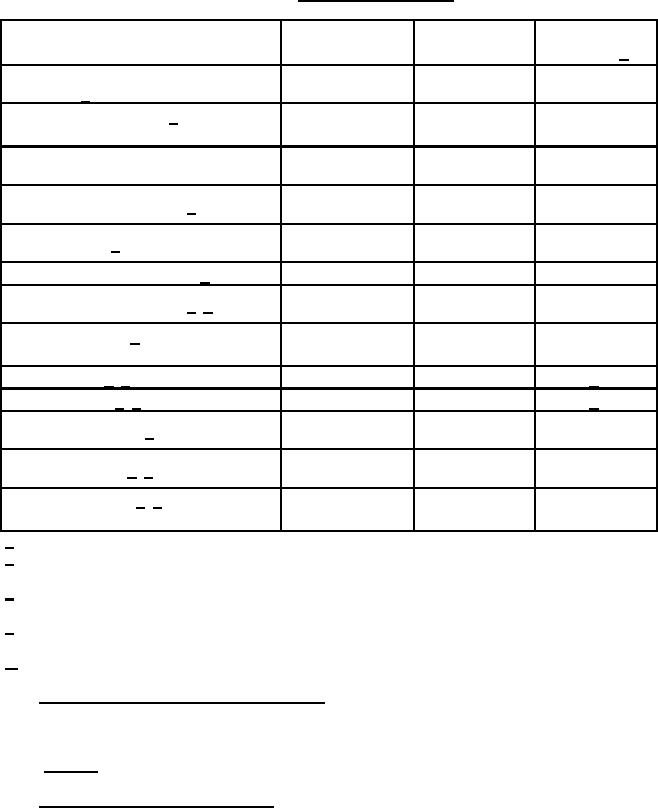

TABLE VI. Qualification inspection.

Requirement

Inspection

Number of

Inspection

samples 4/

paragraph

paragraph

Visual, configuration and mechanical

All

inspection 1/

Salt spray (fittings only) 1/

3 fittings

Visual examination

All hose

Proof pressure

assemblies

3 hose

Elongation and contraction1/

assemblies

3 hose

Burst pressure 1/

assemblies

Vacuum collapse resistance 1/

1 hose

3 hose/ or hose

Low temperature flexibility 1/ 2/

assemblies

Ozone resistance 2/

1 hose

Visual examination

Oil resistance 1/ 2/

5/

Fuel resistance 1/ 2/

5/

6 hose

Vibration resistance 2/

4.7.12

assemblies

2 type III hose

Hot oil circulation 1/ 2/

assemblies

Fungus resistance 2/ 3/

6 hose

assemblies

Proof pressure (30, 60, 90 days)

1/ These are destructive tests.

2/ These tests need only be done during initial qualification as long as materials, material

supplier, and designs and manufacturing processes have not changed.

3/ Manufacturers may certify to the qualifying activity that the materials used are fungus resistant in-

lieu-of performing this test.

4/ Reference the inspection paragraph for specimen sizes and hose or hose assembly sample

lengths.

5/ 3 specimens taken from the cover and 3 specimens taken from the inner tube.

4.5.3 Acceptance of qualification inspection data. Required qualification tests at the hose assembly

level that were already performed at the bulk hose level may be eliminated if documented approval has

been obtained from the qualifying activity.

4.5.4. Failures. One or more failures shall be cause for refusal to grant qualification.

4.5.5 Test plans and qualification reports.

12

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business