MIL-DTL-25579G

4.3.2.2 Nonconformance of sampling tests. If one or more defects are found in the inspection sample, both

the qualifying and inspection activities shall be immediately notified and the production lot shall be rejected and

not be supplied to this specification. Acceptance and shipment of the product shall be discontinued until

corrective action, acceptable to the qualifying activity, has been taken. The corrective measures shall be

performed on the materials or processes, or both, as warranted, and on all products considered subjected to

the same failure. Once the corrective action has been completed, either the specific sampling test in which the

original sample failed or all sampling tests may be required to be repeated on additional samples, at the option

of the qualifying activity. However, final acceptance shall be withheld until testing has shown that the corrective

action was successful. In the event of a failure after re-inspection, information concerning the failure and the

corrective action taken shall be furnished to both the qualifying and inspection activities.

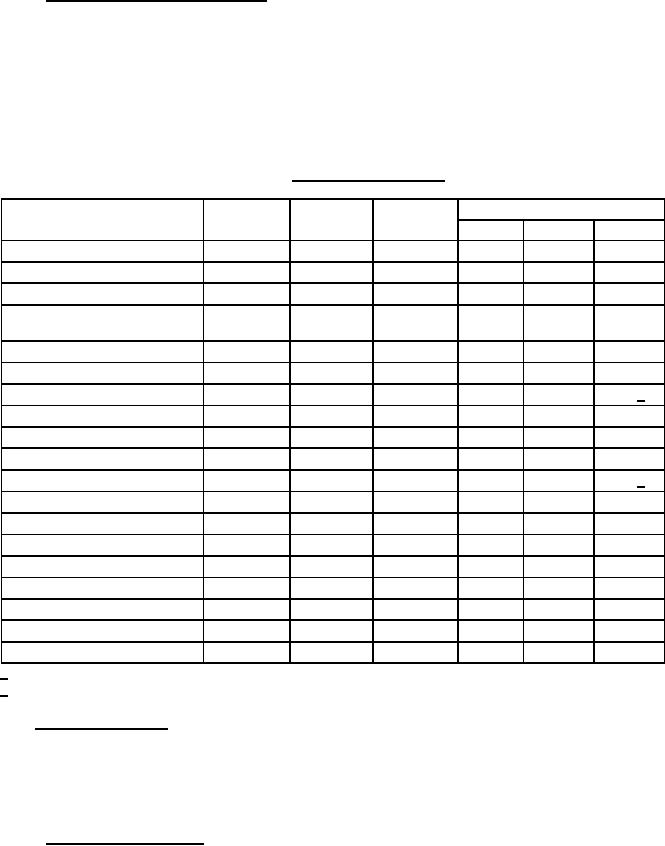

TABLE VI. Inspection requirements.

Requirement

Requirement Test method Qualification

Conformance inspection

paragraph

paragraph

inspection Individual Sampling Periodic

Examination of product

X

X

Proof pressure

X

X

Leakage

X

X

Room temperature burst

X

X

pressure

High temperature burst pressure

X

Hose assembly conductivity

X

X

Impulse

X

X 1/

Fuel resistance

X

Pneumatic effusion

X

Pneumatic surge

X

Stress degradation

X

X 2/

Corrosion

X

Over-tightening torque

X

Elongation & contraction

X

X

Volumetric expansion

X

Low temperature flexibility

X

Vacuum

X

Pneumatic leakage

X

Fire resistance or fire proof

X

1/ Only unaged samples shall be subjected to testing.

2/ Exposure to -67°F (-55ēC) and subsequent testing may be omitted.

4.3.3 Periodic control tests. For each size manufactured under essentially the same conditions, periodic

control testing shall be performed on either eight samples from every 10,000 hose assemblies produced or two

samples from every 2,500 hose assemblies. If there has been some production but the number of hose

assemblies produced has not reached 2,500 for a specific size within three years, the manufacturer shall

perform periodic control tests on two hose assemblies of that size unless documented approval has been

obtained from the qualifying activity.

4.3.3.1 Periodic control test plan. Testing shall be as specified in table VI. Half of the samples shall be

subjected to the stress degradation test followed by the hose conductivity test. The remaining half of the

samples shall be subjected to the impulse test.

14

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business