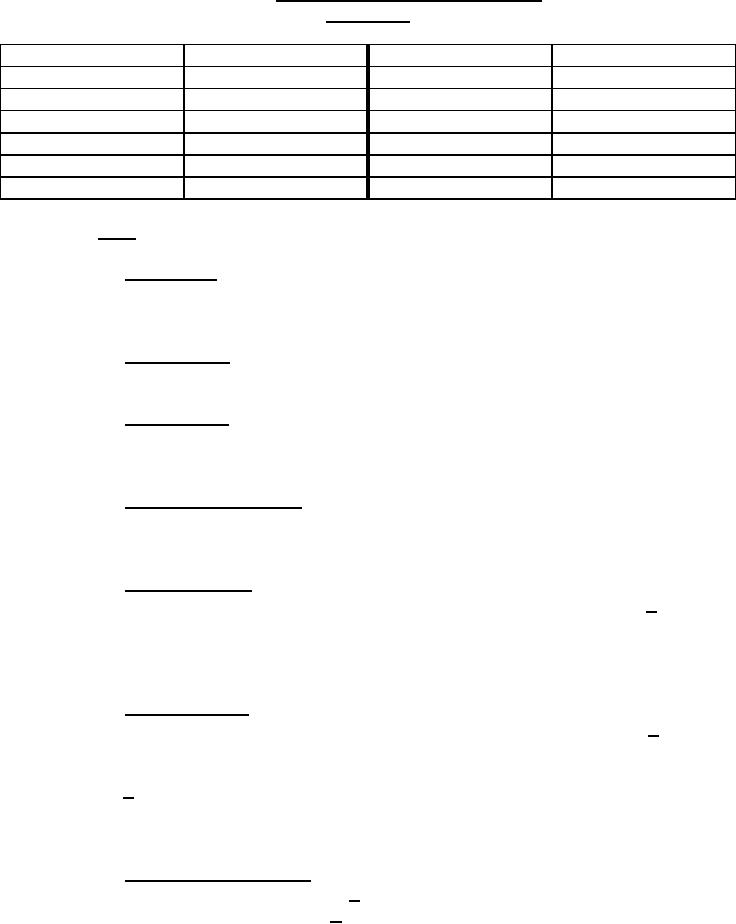

MIL-PRF-26626F

TABLE I. Requirements cross-reference matrix

(continued)

Requirement

Verification

Requirement

Verification

3.3.3

4.6.1

3.5.8

4.6.7

3.4.1

4.6.1

3.5.9

4.6.8

3.4.2

4.6.1

3.5.10

4.6.9

3.4.3

4.6.1

3.5.11

4.6.1

3.5.1

4.6.1

3.5.12

4.6.1

3.5.2

4.6.1

3.6

4.6.1

4.6 Tests.

4.6.1 Examination. The hose assembly shall be examined to determine that the

materials, interface, dimensions, inner liner, identification, and interchangeability conform to this

specification.

4.6.2 Proof pressure. The hose assembly shall be pressurized to 1,000 psig and the leak

rate shall be less than 2 cm3 per minute.

4.6.3 Burst pressure. The hose assembly shall be hydrostatically pressurized to 2,200

psig. While at this pressure, the leak rate shall be less than 2 cm3 per minute and there shall be no

loosening of the end fittings.

4.6.4 Ultimate tensile strength. The hose shall be attached by the fittings and a tensile

force shall be applied at a rate no less than 1 pound per minute until failure. The hose assembly

shall not break at 300 pounds or less.

4.6.5 High temperature. Six hose assemblies shall be coupled together, end-to-end, and

pressurized to 500 psig. The hose assemblies shall be exposed to a temperature of 260o + 5oF for

48 hours. After returning to room temperature, the static pressure remaining shall not be less than

100 psig. The coupled hose assemblies shall then be subjected to the proof pressure test (see

4.6.2).

4.6.6 Low temperature. Six hose assemblies shall be coupled together, end-to-end, and

pressurized to 500 psig. The hose assemblies shall be exposed to a temperature of -65o + 5oF for

48 hours. After returning to room temperature, the static pressure remaining shall not be less

than 100 psig. Liquid oxygen shall then be passed through the coupled hose assemblies at a

pressure of 25 + 5 psig for a period of not less than 5 minutes, and there shall be no evidence of

leakage. The coupled hose assemblies shall then be subjected to the proof pressure test (see

4.6.2).

4.6.7 Low temperature bending. Liquid oxygen or liquid nitrogen shall be passed

through the hose assembly at a pressure of 25 + 5 psig for a period of not less than 15 minutes

and then subjected to a temperature of -65o + 5oF for not less than 30 minutes. While at this

temperature, the hose assembly shall undergo 5 bending cycles allowing 4 seconds per cycle.

7

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business