A-A-55697B

3.6 Flexibility. Tubing shall be capable of bending around a mandrel equal to five times the OD of the

tube without collapsing or restricting flow.

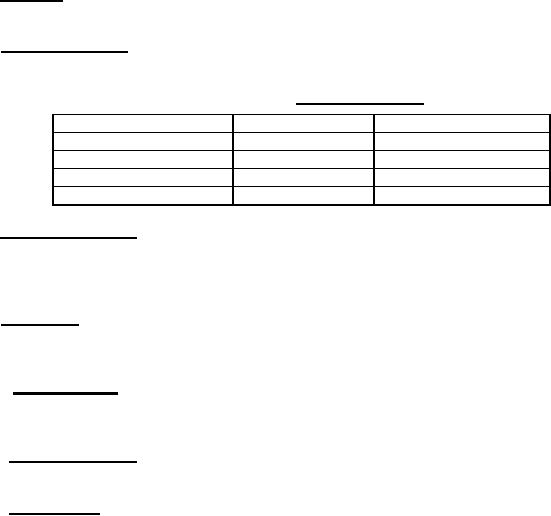

3.7 Physical properties. Physical properties of the tubing shall be as specified in table IV when tested in

accordance with the test method shown.

TABLE IV. Physical properties.

Property

Requirement

Test method

Brittleness temperature

-50.8°F (-46ºC)

ASTM D746

Specific gravity

1.15 - 1.80

ASTM D792

Tensile strength, psi

1800 - 2100

ASTM D638

Elongation, percent

300 minimum

ASTM D638

3.8 Chemical resistance. Tubing shall not discolor, flake, crack or pit when tested in accordance with

USP-NF, Physicochemical Tests-Plastics, ASTM D1003, Standard Method of Test for Haze and

Luminous Transmittance of Transparent Plastics, and ASTM E308, Standard Practice for Computing the

Colors of Objects by Using the CIE System.

3.9 Sterilization. Tubing shall be capable of withstanding sterilization by steam, ethylene oxide, radiation,

or other method that meets the requirements of the USP-NF, Sterility Tests for Transfusion and Infusion

Assemblies and Similar Medical Devices.

3.10. Heat resistance. Tubing shall be capable of withstanding temperatures of 200±5 ºF (93.3±2.8 ºC)

for one hour without visual signs of deterioration such as discoloring, flaking, cracking, pitting, hardening,

or melting.

3.11 Biological reactivity. Tubing shall meet the requirements of USP Class II plastics and the

Association for the Advancement of Medical Instrumentation, AAMI/ANSI 10993-1.

3.12 Metal content. The use of hazardous materials (see 7.2) shall be eliminated or minimized where

possible. Tubes shall not contain more than five parts per million (ppm) of heavy metals, such as lead, in

their ash residue when tested as follows:

a. Two sample tubes shall be selected at random from each lot (lot is defined as a continuous run of

tubing from the same batch or raw material, and offered for delivery under one contract).

b. From each sample accurately weigh a 0.176 oz. (5 gm) sample into one-ounce VYCOR ®

crucibles.

c. Reduce to ash in a muffle furnace at 1202ºF (650ºC) for 8 hours.

d. Let cool to room temperature and add 0.507 fluid ounces (15 ml) of 1:1 hydrochloric acid.

e. Bring to a boil on a hot plate, allow to boil for two to three minutes, remove, let cool and filter

through Whatman grade #2 filter paper (particle retention 8µm) into a 1.691 fluid ounces (50 ml)

volumetric flask.

f. Rinse the residue from the filter with deionized water and dilute to 1.691 fluid ounces (50 ml).

g. Prepare standard lead solutions of one, two, and five ppm lead.

h. Determine the absorbencies of these solutions at the 283 millimicron wavelength using a Hollow

Cathode Pb lamp and 10x scale expansion on an atomic absorption spectrophotometer.

i. Determine the absorbance of the sample solutions using the same conditions as with the standards.

j. The calculated factors of the three standards are averaged to give ppm/unit A.

3

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business